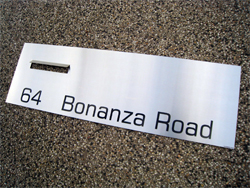

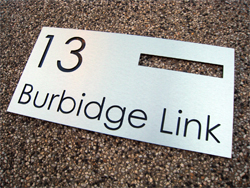

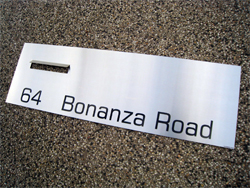

A well designed and manufactured letterbox faceplate can significantly add to the visual impact and prestige of a property.

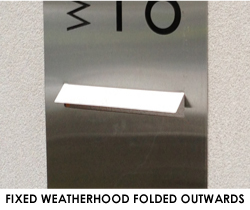

Sassysigns can design and custom cut letterbox faceplates to almost any specification from a variety of materials ranging from acrylic, Alumabond, stainless steel, aluminium, vinyl, MDF, plywood, copper and Corten Steel (weathering steel). For steel based letterbox faceplates, we can also fold fixed weatherhoods (folded inwards, or outwards) as shown below:

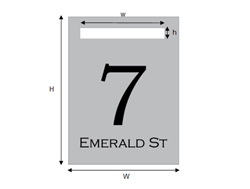

The recommended mail aperture dimensions for a letterbox faceplate is 230mm (W) x 30mm (H). For horizontal apertures, the lower edge of the aperture should be at least 130 mm above the base of the internal space, whilst for vertical apertures, the lower edge of the aperture should be at least 40 mm above the base of the internal space. Australia Post recommends an optimal aperture height of 900mm to 1200mm above ground level.

For custom cut letterbox faceplates, please email us your requirements at sales@sassysigns.com.au.

1. Dimensions and layout of letterbox faceplate

2. Material and finish (i.e. stainless steel, acrylic, alumabond, brushed or polished mirror steel etc)

3. If it is a steel faceplate do you require a fixed weatherhood ? If yes, folded outwards or inwards ?

4. If material is Alumabond, is the faceplate flat or in folded box form (i.e. a folded box as a depth of 25mm) ?

5. Font type and what you want written on the faceplate ?

6. Is the faceplate going to be installed near the sea ?

7. Does the faceplate require illumination ? If yes what colour tone (cool white, warm white or blue ?)

General Letterbox Faceplate Sizing Guidelines

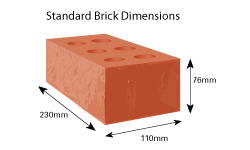

A standard brick measures 230mm W x 76mm H x 110mm D.

Motar gaps are typically about 10mm hence, a single brick cavity is 250mm wide, a 1.5 brick cavity is 370mm wide, and a 2 brick cavity is 490mm wide. The width of a faceplate should be at least 50mm (i.e. 25mm on either side of cavity) wider than the width of the cavity hole. Therefore the minimum width for a letterbox faceplate covering a single brick cavity should be 300mm wide.

Sassysigns is often engaged by builders and architects to fabricate complete custom wall mounted letterbox units (faceplate, sleeve and lockable back flap). A custom fabricated letterbox unit cannot be competitively priced as compared to mass produced units. However, custom letterboxes have the benefits of customisable size and shape, choice of materials and finishes. Unless absolutely neccessary, it is more economical to simply purchase a custom faceplate from Sassysigns, and do without an internal sleeve (i.e. raw brick cavity) while using a standard back flap purchased from a local hardware shop. See example below:

Example Custom Faceplates